Polishing Tools in Everyday Use: Where Finish Quality Is Really Decided

In many workshops and job sites, polishing is treated as the final step — something quick, almost cosmetic. In reality, polishing tools often decide whether a job looks finished or rushed. The difference usually isn’t technique alone. It’s the tool doing the work.

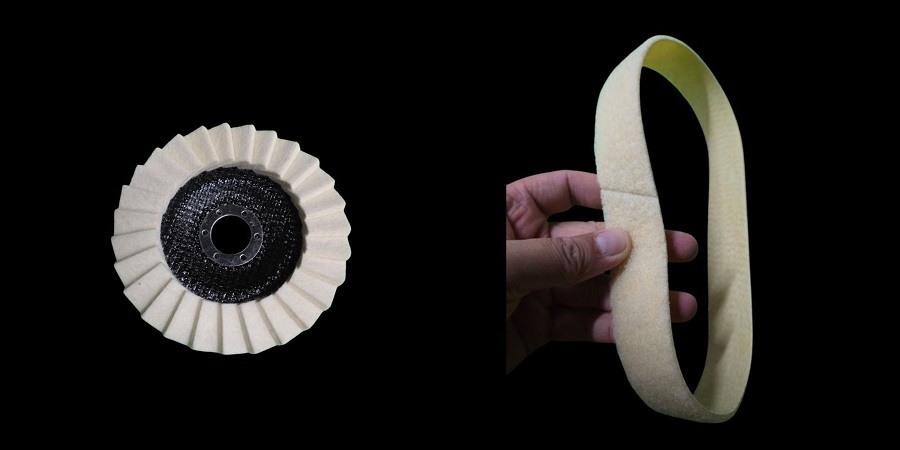

Polishing tools have become essential for a variety of industries like metalworking, stone cutting, automotive, etc. Although such tools do not have an aggressive removal rate like grinding tools, their role is still very important. They not only smooth the surfaces, but also remove their surface imperfections and enhance the final appearance.

If the polishing tools are not working properly, then the defects will be seen. There will be swirl marks. The finish will be uneven. More passes will be required, which means that time will be added and frustration to a job that is already supposed to be finished.

What Makes Polishing Over Controlling Than Force

Polishing is all about controlling and not pressure as in the case of the grinding process. The excellent polishing tools allow the operators to guide the finish smoothly, resulting in less time wasted on holding back. Cheap tools usually cause directing, loose smearing or uneven wearing, leading to non-uniform results.

Trustworthy abrasive polishing tools are made to cover the entire surface of the operative area equally. They maintain their equilibrium, make proper contact distribution, and wear out in a foreseeable manner. This uniformity permits the workers to give their attention to the finish instead of changing their technique every few minutes.

Different Materials Require Different Polishing Tools

One of the biggest mistakes made in the polishing process is to think of a single tool as capable of working on every type of surface. The metals, stones, composites, and concrete all react differently to polishing pressure. Therefore, using the wrong tool incites heat generation, damage to the surface, or loss of shine.

Suppliers who understand how abrasive polishing tools behave on different materials help reduce trial and error. This knowledge becomes especially valuable in repetitive work, where consistent finishes are expected every time.

Tool Consistency Matters More Than Appearance

In real working conditions, appearance on the shelf matters less than performance on the surface. Polishing tools that change behavior from one batch to the next create uncertainty. Operators compensate by slowing down or applying uneven pressure, which affects finish quality.

Staying with the same tools makes processes easier. As soon as the operator has the polishing tool response, the workflow becomes smoother and easier to predict. This helps to keep the workers from getting tired, and thus, the finish quality becomes uniform over many jobs.

Patterns of Wearing and Longevity Affect the Results

Polishing tools that wear unevenly do not have a smooth and even cut, and this causes marks or shades that are not uniform. This is very often not noticed until the final inspection. Dual-wear and gradual-wearing tools bear contact with the surface longer, the result being fewer corrections than before.

In many situations, the durable abrasive polishing tools reduce the cost of the whole operation since the early replacement is not needed and there is no rework. Though there is a difference in price at the beginning, the consistency in the long run is usually much more valuable than the short-term savings.

Polishing Tools as Part of the Overall Process

Polishing is not a single step but rather a whole chain of events that starts with preparation and continues with the selection of a suitable tool depending on the material condition. The treatment of polishing tools as interchangeable consumables often results in inconsistent outcomes.

When polishing tools behave as expected, they do not attract attention to themselves. They just perform their function – silently perfecting surfaces and closing the work.

0 Comments